Almost 3 years 3 months ago I started my professional life with Screw Piles (or helical piles). My initial training taught me that this item is used to make foundations of houses, decks and patios et cetera. The developed countries use this item very much and day by day its use is growing. Since this is a very sensitive item, the quality control HAS to be stringent. A poor item may result in accidents causing harm to human and animals both.

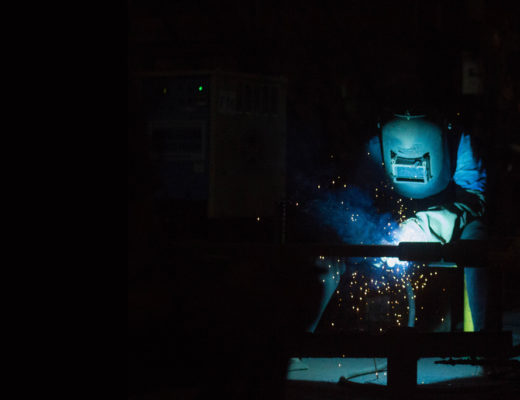

It is interesting to spend time in the fabrication house watching the nuts and bolts of the fabrication process of screw piles. The fabrication team is an unison of scores of people committed to individual responsibilities. Knowing the clients' requirements, selecting the quality tubes, inspection before fabrication, a quality fabrication process and finally surface finish.

As a fabricator, one must keep in mind, the piles HAVE to be strong to endure the variable loads for years to come. Staying 'naked' underground subjects them to erosion caused by the soil. Hence the surface protection by galvanization or paint are preferred by some of our clients.

A thorough manual check after the surface coating is a good practice to ensure the right finishing both in terms of durability and aesthetics.